Table of Contents

UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, DC 20549

FORM 10-K

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For The Fiscal Year Ended March 31, 2012

o TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from to

Commission File Number: 001-35159 (Thermon Group Holdings, Inc.)

Commission File Number: 333-168915-05 (Thermon Holding Corp.)

THERMON GROUP HOLDINGS, INC.

THERMON HOLDING CORP.

(Exact name of registrant as specified in its charter)

|

Delaware (Thermon Group Holdings, Inc.)

Delaware (Thermon Holding Corp.)

(State or other jurisdiction of incorporation or organization) |

|

27-2228185 (Thermon Group Holdings, Inc.)

26-0249310 (Thermon Holding Corp.)

(IRS Employer Identification No.) |

|

|

|

|

|

100 Thermon Drive, San Marcos, Texas

(Address of principal executive offices) |

|

78666

(Zip Code) |

(512) 396-5801

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

Thermon Group Holdings, Inc.

|

Title of each class |

|

Name of each exchange

on which registered |

|

Common Stock, $0.001 par value per share |

|

New York Stock Exchange |

Thermon Holding Corp.

|

Title of each class |

|

Name of each exchange

on which registered |

|

None |

|

Not applicable |

Securities registered pursuant to Section 12(g) of the Act:

Thermon Group Holdings, Inc.: None

Thermon Holding Corp.: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

|

Thermon Group Holdings, Inc. o Yes x No |

|

Thermon Holding Corp. o Yes x No |

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Act.

|

Thermon Group Holdings, Inc. o Yes x No |

|

Thermon Holding Corp. o Yes x No |

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

|

Thermon Group Holdings, Inc. x Yes o No |

|

Thermon Holding Corp. o Yes x No |

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files).

|

Thermon Group Holdings, Inc. x Yes o No |

|

Thermon Holding Corp. x Yes o No |

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K (§229.405 of this chapter) is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K.

|

Thermon Group Holdings, Inc. o |

|

Thermon Holding Corp. x |

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company in Rule 12b-2 of the Exchange Act.

|

Thermon Group Holdings, Inc. |

|

Large accelerated filer o |

|

Accelerated filer o |

|

|

|

|

|

Non-accelerated filer x |

|

Smaller reporting company o |

|

Large accelerated filer o |

|

Accelerated filer o |

|

|

|

|

|

Non-accelerated filer x |

|

Smaller reporting company o |

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

|

Thermon Group Holdings, Inc. o Yes x No |

|

Thermon Holding Corp. o Yes x No |

The aggregate market value of Thermon Group Holdings, Inc.’s common equity held by non-affiliates as of September 30, 2011 was $217,357,325 based on the closing price of $13.82 as reported on the New York Stock Exchange. Solely for the purposes of this calculation, directors and officers of the registrant are deemed to be affiliates. Thermon Holding Corp. is a wholly-owned subsidiary of Thermon Group Holdings, Inc., and therefore the market value of its common equity held by non-affiliates as of September 30, 2011 was zero.

As of June 4, 2012, each registrant had the following number of shares of common stock outstanding:

Thermon Group Holdings, Inc.: 30,351,412 shares, par value $0.001 per share

Thermon Holding Corp.: 100,000 shares, par value $0.001 per share. Thermon Group Holdings, Inc. is the sole stockholder of Thermon Holding Corp. common stock.

DOCUMENTS INCORPORATED BY REFERENCE

As permitted by General Instruction G of Form 10-K, certain portions, as expressly described in this report, of Thermon Group Holdings, Inc.’s Definitive Proxy Statement for the 2012 Annual Meeting of Stockholders are incorporated by reference into Part III of this Annual Report on Form 10-K.

Thermon Holding Corp. meets the conditions set forth in General Instruction I(1)(a) and (b) of Form 10-K and is therefore filing this Form with the reduced disclosure format.

Table of Contents

EXPLANATORY NOTE

This annual report (“this annual report”) combines the Annual Reports on Form 10-K for the year ended March 31, 2012 of Thermon Group Holdings, Inc. and Thermon Holding Corp.

Unless stated otherwise or the context otherwise requires, references in this annual report to:

· “TGH” mean Thermon Group Holdings, Inc., a Delaware corporation;

· “THC” mean Thermon Holding Corp., a Delaware corporation;

· “we,” “our,” “us”, “Thermon” or “the Company” mean TGH, THC and their consolidated subsidiaries taken together as one company; and

· a particular fiscal year are to the twelve months ended on March 31 of the given calendar year (e.g., “fiscal 2012” and “fiscal 2011” mean the Company’s fiscal years ended March 31, 2012 and March 31, 2011, respectively).

TGH was incorporated in Delaware in March 2010 in connection with the acquisition by an affiliate of CHS Capital LLC, or CHS, of a majority interest in us on April 30, 2010, which we refer to, together with certain transactions related to such acquisition described below, as the CHS Transactions. TGH is the sole stockholder of THC.

THC is a direct wholly-owned subsidiary of TGH and was incorporated in Delaware in 2007 in connection with the acquisition by an affiliate of the Audax Group private equity firm, or Audax, of a majority interest in us in August 2007, which we refer to as the Audax Transaction.

TGH is a holding company that conducts all of its business through THC and its subsidiaries. In May 2011, TGH completed an initial public offering, or the IPO, of its common stock. In the aggregate, 10,650,000 shares of TGH common stock were sold in the IPO at a price to the public of $12.00 per share. TGH’s common stock, which we refer to as our common stock, is listed on the New York Stock Exchange, which we refer to as the NYSE, under the symbol “THR.”

THC owns 100% of the outstanding shares of common stock of Thermon Industries, Inc. (“TII”), which issued $210,000,000 aggregate principal amount of 9.500% Senior Secured Notes due 2017, which have been registered with the Securities and Exchange Commission (or “SEC”) under the Securities Act of 1933, as amended (or the “Securities Act”), and which we refer to as our senior secured notes. THC and the domestic subsidiaries of TII are guarantors of our senior secured notes.

We believe combining the Annual Reports on Form 10-K of TGH and THC into this single report provides the following benefits:

· it enhances investors’ understanding of TGH and THC by enabling investors to view the business as a whole in the same manner as management views and operates the business;

· it eliminates duplicative disclosure and provides a more streamlined and readable presentation since a substantial portion of the disclosure applies to both TGH and THC; and

· it creates time and cost efficiencies for both companies through the preparation of one combined report instead of two separate reports.

In order to highlight the differences between TGH and THC, there are sections in this annual report that separately discuss TGH and THC, including separate financial statements and notes thereto and separate Exhibit 31 and Exhibit 32 certifications. Cash and cash equivalents and stockholders’ equity are the main areas of difference between the consolidated financial statements of TGH and those of THC. In the sections that combine disclosure for TGH and THC (i.e., where the disclosure refers to the consolidated company), this annual report refers to actions or holdings as our actions or holdings and, unless otherwise indicated, means the actions or holdings of TGH and THC and their respective subsidiaries, as one consolidated company.

Table of Contents

FORWARD-LOOKING STATEMENTS

This annual report includes forward-looking statements within the meaning of the U.S. federal securities laws in addition to historical information. These forward-looking statements are included throughout this annual report, including in the sections entitled “Risk Factors,” “Management’s Discussion and Analysis of Financial Condition and Results of Operations” and “Business” and include, without limitation, statements regarding our industry, business strategy, plans, goals and expectations concerning our market position, future operations, margins, profitability, capital expenditures, liquidity and capital resources and other financial and operating information. When used in this discussion, the words “anticipate,” “assume,” “believe,” “budget,” “continue,” “could,” “estimate,” “expect,” “intend,” “may,” “plan,” “potential,” “predict,” “project,” “will,” “future” and similar terms and phrases are intended to identify forward-looking statements in this annual report.

Forward-looking statements reflect our current expectations regarding future events, results or outcomes. These expectations may or may not be realized. Some of these expectations may be based upon assumptions, data or judgments that prove to be incorrect. In addition, our business and operations involve numerous risks and uncertainties, many of which are beyond our control, which could result in our expectations not being realized or otherwise materially affect our financial condition, results of operations and cash flows. The statements include but are not limited to statements regarding: (i) our plans to strategically pursue emerging growth opportunities in diverse regions and across industry sectors; (ii) our plans to secure more new facility, or Greenfield, project bids; (iii) our ability to generate more facility maintenance, repair and operations or upgrades or expansions, or MRO/UE, revenue from our existing and future installed base; (iv) our ability to timely deliver backlog; (v) our ability to respond to new market developments and technological advances; (vi) our expectations regarding energy consumption and demand in the future and its impact on our future results of operations; (vii) our plans to develop strategic alliances with major customers and suppliers; (viii) our expectations that our revenues will continue to increase; (ix) our belief in the sufficiency of our cash flows to meet our needs for the next year; and (x) our expectations regarding anticipated benefits from the recently completed expansion of our principal manufacturing facility in San Marcos, Texas.

Actual events, results and outcomes may differ materially from our expectations due to a variety of factors. Although it is not possible to identify all of these factors, they include, among others, (i) general economic conditions and cyclicality in the markets we serve; (ii) future growth of energy and chemical processing capital investments; (iii) changes in relevant currency exchange rates; (iv) our ability to comply with the complex and dynamic system of laws and regulations applicable to international operations; (v) a material disruption at any of our manufacturing facilities; (vi) our dependence on subcontractors and suppliers; (vii) our ability to obtain standby letters of credit, bank guarantees or performance bonds required to bid on or secure certain customer contracts; (viii) competition from various other sources providing similar heat tracing products and services, or other alternative technologies, to customers; (ix) our ability to attract and retain qualified management and employees, particularly in our overseas markets; (x) our ability to continue to generate sufficient cash flow to satisfy our liquidity needs; and (xi) the extent to which federal, state, local and foreign governmental regulation of energy, chemical processing and power generation products and services limits or prohibits the operation of our business. Any one of these factors or a combination of these factors could materially affect our future results of operations and could influence whether any forward-looking statements contained in this annual report ultimately prove to be accurate. See also Item 1A, “Risk Factors” for information regarding the additional factors that have impacted or may impact our business and operations.

Our forward-looking statements are not guarantees of future performance, and actual results and future performance may differ materially from those suggested in any forward-looking statements. We do not intend to update these statements unless we are required to do so under applicable securities laws.

ii

Table of Contents

PART I

ITEM 1. BUSINESS

Business Overview

We are one of the largest providers of highly engineered thermal solutions for process industries. For almost 60 years, we have served a diverse base of thousands of customers around the world in attractive and growing markets, including energy, chemical processing and power generation. We are a global leader and one of the few thermal solutions providers with a global footprint and a full suite of products (heating cables, tubing bundles and control systems) and services (design optimization, engineering, installation and maintenance services) required to deliver comprehensive solutions to complex projects. We serve our customers locally through a global network of sales and service professionals and distributors in more than 30 countries and through our four manufacturing facilities on three continents. These capabilities and longstanding relationships with some of the largest multinational energy, chemical processing, power and engineering, procurement and construction, or EPC, companies in the world have enabled us to diversify our revenue streams and opportunistically access high growth markets worldwide. For fiscal 2012, approximately 66% of our revenues were generated outside of the United States.

Our thermal solutions, also referred to as heat tracing, provide an external heat source to pipes, vessels and instruments for the purposes of freeze protection, temperature and flow maintenance, environmental monitoring, and surface snow and ice melting. Customers typically purchase our products when constructing a new facility, which we refer to as Greenfield projects, or when performing maintenance, repair and operations on a facility’s existing heat-traced pipes or upgrading or expanding a current facility, which we refer to collectively as MRO/UE. A large processing facility may require our thermal solutions for a majority of its pipes, with the largest facilities containing hundreds of thousands of feet of heat-tracing cable and thousands of control points. Our products are low in cost relative to the total cost of a typical processing facility, but critical to the safe and profitable operation of the facility. These facilities are often complex, with numerous classified areas that are inherently hazardous and where product safety concerns are paramount. We believe that our strong brand and established reputation for safety, reliability and customer service are critical contributors to our customers’ purchasing decisions.

Our customers’ need for MRO/UE solutions provides us with an attractive recurring revenue stream. Customers typically use the incumbent heat tracing provider for MRO/UE projects to avoid complications and compatibility problems associated with switching providers. We typically begin to realize meaningful MRO/UE revenue from new Greenfield installations one to three years after completion of the project as customers begin to remove and replace our products during routine and preventative maintenance on in-line mechanical equipment, such as pipes and valves. As a result, our growth has been driven by new facility construction, as well as by servicing our continually growing base of solutions installed around the world, which we refer to as our installed base. Approximately 61% of our revenues for fiscal 2012 were derived from such MRO/UE activities.

Our corporate offices are located at 100 Thermon Drive, San Marcos, TX 78666. Our telephone number is (512) 396-5801. Our website address is www.thermon.com. Copies of the charters of the committees of our board of directors, our code of business conduct and ethics and our corporate governance guidelines are available on our website. All reports that we have filed with the Securities and Exchange Commission (“SEC”), including this Annual Report on Form 10-K and our Current Reports on Form 8-K, can be obtained free of charge from the SEC’s website at www.sec.gov or through our website. In addition, all reports filed with the SEC may be read and copied at the SEC’s Public Reference Room at 100 F Street, NE, Washington, D.C. 20549-1090. Further information regarding the operation of the public reference room may be obtained by calling the SEC at 1-800-SEC-0330. None of the information on our website or any other website identified herein is incorporated by reference in this annual report and should not be considered a part of this annual report.

1

Table of Contents

Company History

Thermon Manufacturing Company, historically our principal operating subsidiary, was founded as a partnership in October 1954 and later incorporated in Texas in 1960. At that time, our primary product was a thermally conductive heat transfer compound invented by our founder, Richard Burdick. Under Mr. Burdick’s leadership, we experienced steady growth by diversifying our products and expanding our geographic reach. Mr. Burdick and his family maintained a controlling interest in us until August 2007, when the controlling interest was sold to an affiliate of the Audax Group private equity firm in the Audax Transaction. During Audax’s tenure as our majority owner, we positioned ourselves to take advantage of rising demand in the energy end market and secured significant capital projects. Over the last five years, our management team has focused on significant organic growth opportunities, particularly in high growth markets such as the Canadian oil sands region and Russia.

On April 30, 2010, an investor group led by entities affiliated with CHS Capital LLC and two other private equity firms, which we refer to collectively as our private equity sponsors, acquired Audax’s controlling interest in us. The acquisition and related transaction fees and expenses were financed through (i) the issuance of $210.0 million aggregate principal amount of our senior secured notes and (ii) a $129.3 million equity investment by our private equity sponsors and certain members of our current and former management team. Concurrent with the closing of the acquisition, our wholly-owned subsidiary TII entered into a five-year, $40.0 million senior secured revolving credit facility, which we refer to as our revolving credit facility, of which up to $20.0 million is available to our Canadian subsidiary, subject to borrowing base availability. As used in this annual report, the “CHS Transactions” refer collectively to such acquisition, the equity investment in us by CHS, our other private equity sponsors and certain members of our management team, the entry into our revolving credit facility, the repayment of amounts owed under, and the termination of, certain then-existing revolving credit and term loan facilities, the issuance of our senior secured notes and the application of the gross proceeds from the offering of our senior secured notes and the equity investment to complete such acquisition and to pay related fees and expenses of these transactions.

In May 2011, in connection with the IPO, affiliates of CHS sold 4,307,161 shares of our common stock for approximately $48.1 million, and our other private equity sponsors and their respective affiliates in the aggregate sold 1,613,497 shares of our common stock for approximately $18.0 million. At June 4, 2012, CHS and its affiliates beneficially owned 31.2% of our common stock, and our other private equity sponsors in the aggregate beneficially owned 20.4% of our common stock. We realized net proceeds from the IPO of approximately $48.6 million, after deducting the underwriting discounts and commissions and estimated offering expenses.

2

Table of Contents

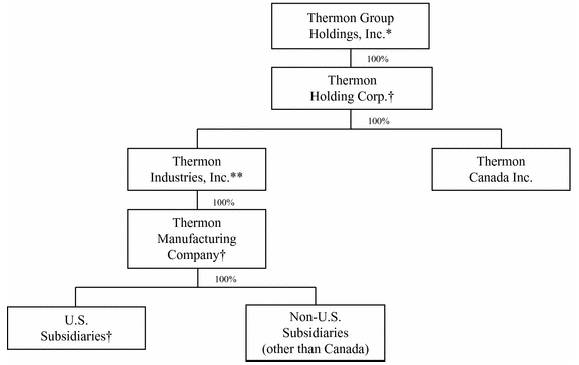

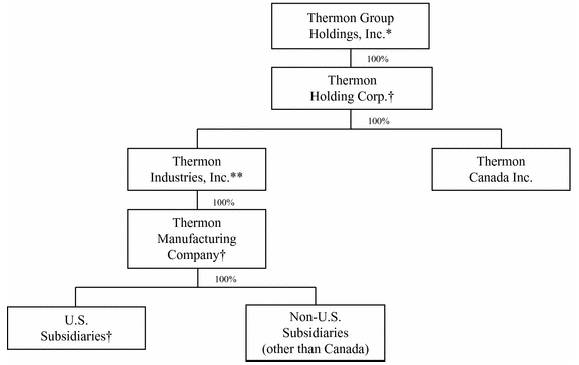

The following chart summarizes our corporate structure:

* Issuer of common stock listed on the New York Stock Exchange under the symbol “THR” and successor for financial statement reporting purposes to Thermon Holdings, LLC, which, as of the completion of the CHS Transactions on April 30, 2010, no longer owned any interest in us.

** Issuer of our SEC-registered senior secured notes

† Guarantor of our SEC-registered senior secured notes

Industry Overview

Alvarez & Marsal Private Equity Performance Improvement Group, LLC, or A&M, estimates that the market for industrial electric heat tracing is approximately $1.2 billion in annual revenues and estimates that it is growing its share of the overall heat tracing market as end users appear to continue to favor electric heat tracing solutions over steam heat tracing solutions for new installations. When revenues for steam heat tracing parts are included, A&M estimates the overall addressable market for heat tracing to be approximately $2.6 billion in annual revenues. The industrial electric heat tracing industry is fragmented and consists of approximately 40 companies that typically only serve discrete local markets with manufactured products and provide a limited service offering. Heat tracing providers differentiate themselves through the quality and reputation of their products, the length and quality of their customer relationships and their ability to provide comprehensive solutions. Large multinational companies drive the majority of spending for the types of major industrial facilities that require heat tracing, and we believe that they prefer providers who have a global footprint and a comprehensive suite of products and services. We believe we are one of only a few companies that meet these criteria.

The major end markets that drive demand for heat tracing include energy, petrochemical and power generation. We believe that there are attractive near- to medium-term trends in each of these end markets. In addition, we believe that the growth rate of the electric heat tracing market is accelerating as end-users continue to favor electric-based heat tracing solutions over steam-based heat tracing solutions for new installations.

· Energy. Heat tracing is used to facilitate the processing, transportation and freeze protection of energy products in both upstream and downstream oil and gas applications. In order to meet growing demand and offset natural declines in existing oil and gas production, a significant increase in capital expenditures in upstream infrastructure will be required, with a particular focus on reservoirs that are in harsher climates, are deeper or have other complex characteristics that magnify the need for heat tracing. A&M estimates that the oil and gas end market accounted for approximately 61% of the total market for electric heat tracing in 2011. Wood Mackenzie, a leading independent energy research and

3

Table of Contents

consulting firm, as of September 2011, expects global upstream development expenditures to increase 15.5% to approximately $477 billion in 2013 from approximately $413 billion in 2010. An increase in upstream production coupled with increased demand for refined products will require a corresponding increase in downstream refining capacity.

· Chemical Processing. Heat tracing is required for temperature maintenance and freeze protection in a variety of chemical processing applications. Factors that may impact heat tracing demand in chemicals end markets include the rapid industrialization of the developing world, a shift in base chemical processing operations to low-cost feedstock regions, a transition of Western chemical processing activities from commodity products to specialty products and environmental compliance. A&M estimates that the chemicals end market accounted for approximately 10% of the total market for electric heat tracing in 2011. According to the American Institute of Chemical Engineers, global capital spending by the chemicals industry is expected to increase to $803.2 billion in 2016, representing a compound annual growth rate of 9.6% from 2010 to 2016.

· Power Generation. Heat tracing is required in high-temperature processes, freeze protection and environmental regulation compliance in coal and gas facilities and for safety injection systems in nuclear facilities. An important driver of demand for heat tracing solutions for power generation is increasing demand for electricity worldwide. A&M estimates that the power generation end market accounted for approximately 23% of the total market for electric heat tracing in 2011. The U.S. Energy Information Administration, or EIA, projects that global net electricity generation will increase 87% between 2007 and 2035. We believe capital spending on new and existing power generation infrastructure will be required to meet this demand.

· Continuing selection of electric-based heat tracing solutions over steam-based solutions. Beginning in the 1960s, electric heat tracing products entered the market as an alternative to steam heat tracing products. While steam-based products are still used today for heavy oil, chemical and processing applications, electric-based products generally offer greater cost savings and operating efficiencies. As a consequence, Greenfield projects commissioned in recent years are increasingly designed to incorporate electric heat tracing.

Segments

We operate in one operating segment, thermal engineered solutions. We have further defined our operating segment based on two geographic regions; Eastern Hemisphere and Western Hemisphere. See Note 17, “Geographic Information” to the consolidated financial statements of TGH for fiscal 2012 contained elsewhere in this annual report for geographic financial data relating to our business.

Products and Services

Our products include a wide range of electric heat tracing cables, steam tracing components, and tubing bundles, as well as instrument and control products, including:

· self-regulating and power limiting heating cables, which automatically increase or decrease heat output as pipe temperature changes;

· mineral insulated, or MI, cable, which is a high performance heat tracing cable for generating high temperatures that is typically used in harsh environments;

· heat traced tube bundles for environmental gas sampling systems;

· heat transfer compounds and steam tracers for comprehensive steam tracing solutions;

· control and monitoring systems for electric tracing of pipes, tanks, hoppers and instrument sampling systems; and

· turnkey solutions that provide customers with complete solutions for heat tracing, including design, optimization, installation and ongoing maintenance.

Electric Heat Tracing Applications

We manufacture critical components of an electric heat tracing system, including heating cables, control and monitoring systems and heating systems for tanks and hoppers. We customize these products to fit the specific design parameters for each client’s installation. We offer various electric heating cables, including conductive polymer self-regulating heating cables, power limiting cables and MI high temperature heating cables.

4

Table of Contents

Self-regulating heating cables—Our self-regulating heating cables are flexible and engineered to automatically increase or decrease heat output as pipe or vessel temperature changes. BSX™ self-regulating cables are designed to provide freeze protection or process temperature maintenance to metallic and non-metallic piping, vessels and equipment. HTSX self-regulating heating cable is suitable for heat tracing applications involving crude oil and most chemicals. VSX™ premium self-regulating cable is rated for maintenance temperatures of 300°F/149°C and exposure temperatures of up to 450°F/232°C and has among the highest self-regulating temperature ratings in the industry.

Power-limiting and constant watt heating cables—Power limiting and constant watt heating cables are flexible parallel resistance cables used to heat trace piping in lengths longer than 500 feet. Such intermediate lengths of pipe are commonly found in pipe racks that connect process units within the plant. These heaters allow longer lengths between power supply points than self-regulating cables.

TEK™ HTEK™ and MIQ™ cables—The TEK™ and HTEK™ series resistance, constant watt heating cables are used where circuit lengths exceed the limitations of parallel resistance heating cables. By using series constant watt heating cables, a single power supply point can energize circuit lengths up to 12,000 feet. MIQ™ high performance mineral insulated heating cables are used for high temperature maintenance, high temperature exposure and/or high watt density applications that exceed the limitations of thermoplastic insulated cables. MIQ™ cables are composed of a high nickel/chromium alloy sheath, which is well-suited for high temperature service and offers high resistance to stress corrosion in chloride, acid, salt and alkaline environments.

Steam Heat Tracing

In 1954, we began manufacturing heat transfer compounds that greatly improved the heat delivery of steam tracing systems. Today, in addition to the broad range of heat transfer compounds, we also offer steam tracers and tubing bundles that provide our customers with comprehensive steam tracing solutions. We manufacture our heat transfer compounds in various configurations so that they can be applied to different surfaces, which increases the heat transfer rate of steam or fluid tracers.

Our heat transfer compounds create an efficient thermal connection between the heat tracing system and the process equipment. Through the elimination of air voids, heat is directed into the pipe wall primarily through conduction rather than convection and radiation. This requires fewer tracing pipes to maintain specified temperature requirements, substantially reducing operating and investment cost. Steam tracing offers the most cost effective solution for certain heavy oil and natural gas processing applications.

Temperature Controls and Monitoring

We supply a wide range of control and monitoring products, from simple mechanical thermostats to sophisticated microprocessor-based systems that control and monitor the status of electric heat tracing systems. We provide individual units for smaller projects, as well as multi-point controllers that can be integrated into and communicate with a plant’s central operating controls.

During fiscal 2012, we introduced the latest version of our TraceNet temperature control monitoring system. This technology allows up to 180 monitoring circuits to be controlled from a single control module. Previous versions of the controller could control 18 circuits.

The temperature controllers work in conjunction with our TraceView control system software. The TraceView system collects and analyzes data from all heat tracing sensors of a facility, which is then analyzed and controlled by a single technician at a workstation.

The most recent version of our TraceView control system software provides three critical improvements over other available applications:

· it processes information faster, substantially reducing data collection time at large facilities with thousands of heat tracing circuits;

· it provides for increased data collection and functionality, thereby increasing plant safety and efficiency; and

· it allows for improved communications with distributed control systems, which are used to control equipment (such as valves) in industrial facilities.

5

Table of Contents

Instrumentation

We specialize in pre-insulated and heat-traced tubing bundles with accessories that offer a complete instrument heating system. Our complete range of products includes both electric- and steam-heated bundles containing various types of tubing (such as copper, stainless steel and polymer) to meet the needs of process and environmental applications. Such applications include transporting samples of gas or liquid in our customized, temperature-controlled tubing bundles to an instrument that typically performs an analysis for purposes of process management or ensuring compliance with internal requirements or applicable environmental laws and regulations.

Tank Insulation and Heating Systems

In 1992, we introduced the ThermaSeam™ Tank Insulation System, which provides a product for insulating large vessels that commonly contain petroleum, chemical, asphalt, anhydrous ammonia, beverages or chilled water for HVAC storage. The design of the ThermaSeam™ Tank Insulation Systems enables installation without the use of scaffolding and is durable, low maintenance and cost-effective. The machine-formed, double-locking standing seams between adjacent panels that create a weatherproof barrier and also extend the entire height of the tank enhance the system’s strength and durability. The system’s external banding eliminates traditional weak spots in the tank insulation process. In addition to ThermaSeam™, we also offer the RT FlexiPanel® flexible heating panel, designed specifically for use on metallic tanks or vessels.

Hopper Heating

The HT Hopper Heating Module is a self-contained heater designed for operation on surfaces prone to vibration. In cement plants and fossil fuel power facilities, hoppers facilitate the filtering of a facility’s ash emissions. Hopper heaters maintain the walls of the hopper at a temperature above the dew point to prevent moisture from combining with ash, thus clogging the filtering equipment. We engineer each system based on the heating requirements of the specific application. The HT Hopper Heating Module has multiple flow paths for electrical current, which eliminates the burnout potential common with series wire-based designs. Protection of the heating element from vibration is accomplished with a cushion layer of insulation that also directs the flow of heat from the module to the surface being heated. The module provides mechanical protection during handling, installation and operation, and its low profile design helps facilitate installation.

Turnkey Services

We provide customers with complete turnkey solutions for their heat tracing needs. Turnkey services include project planning, product supply, engineering services, system integration, installation, commissioning and maintenance. Specialized, turnkey heat tracing services meet the needs of many of our industrial customers who have downsized and outsourced their non-core competencies and are requiring their vendor base to have multi-service and multi-site capabilities.

Our turnkey business in the United States is based in Houston, Texas and Baton Rouge, Louisiana. We currently have over 200 turnkey clients; the largest project as of the date of this annual report is approximately $14 million. Engineering and construction companies in the United States often subcontract their heat tracing projects to outside parties, including us, because of the field’s highly specialized nature.

Value-Added Services

We offer heat tracing design and engineering services during every stage of a project. Offering these value-added services, especially during the early stages of a project, is a core element of our business strategy. Based on past experience, the performance of design and engineering services during the early stages of a project leads to subsequent sales of heat tracing products for that project.

We are focused on providing comprehensive solutions to fulfill the heat tracing needs of our customers. As a manufacturer of a wide range of heat tracing products, we believe that we are well positioned to evaluate and optimize a system for a customer without bias towards a particular product, and rely on more than 58 years of experience to craft the most appropriate heat tracing solution for a customer’s situation and demands.

We provide value-added design and engineering services to our customers through our full-time staff of engineers and technicians. Through the design and engineering process, our engineers and technicians located throughout the world provide our customers with design optimization studies, product selection assistance, computer-generated drawing packages and detailed wiring diagrams.

6

Table of Contents

Manufacturing and Operations

We have four manufacturing facilities on three continents. We manufacture the products that generate a majority of our total sales at our principal facility in San Marcos, Texas including flexible heating cables, heat tracing compound and tubing bundles. Our facilities are highly automated, which reduces labor costs. Our facilities incorporate numerous manufacturing processes that utilize computer-controlled equipment and laser technology. We maintain a ready supply of spare parts and have on-site personnel trained to repair and perform preventative maintenance on our specialized equipment, reducing the likelihood of long term interruptions at our manufacturing facilities. Our manufacturing facilities are equipped to provide us with maximum flexibility to manufacture our products efficiently and with short lead times. This in turn allows for lower inventory levels and faster responses to customer demands.

In April 2012, we opened a new manufacturing building at our production facility in San Marcos, Texas. The expansion was completed over the course of one year at an approximate cost of $5.8 million. The new manufacturing building has approximately 48,000 square feet of floor space, including offices. In addition to purchasing new manufacturing equipment, we have moved certain of our existing manufacturing lines to the new building, which we believe will create efficiencies in the cable production process. The new manufacturing building will enable us to approximately double production capacity for our low temperature cables, as well as increase our high temperature cable production capacity by approximately 30%. We currently estimate that the facility expansion, when operating at full capacity, will support revenue levels of up to $400 to $500 million. This should satisfy our core cable growth needs for the next several years, assuming that current trends in product mix continue.

Our electronic cross-linking facility, which we refer to as our ECLF, is also located at the San Marcos facility. Cross-linking enhances the thermal, chemical and electrical stability of our low-temperature self-regulating heater cables. By performing cross-linking in-house, we condense the overall manufacturing cycle by approximately six weeks. This enhances our ability to ensure a high level of product quality and to better control the production process. We also process third party materials, including diamonds, in our ECLF under toll processing agreements in order to increase utilization and generate incremental revenues.

Our pre-insulated tubing products are manufactured in our facilities in San Marcos and the Netherlands. The majority of our pre-insulated tubing product is custom ordered and made to customers’ specifications in a two-part process. The thermal insulation is first applied over the heating cable and process tubing, and a protective plastic outer jacket is extruded onto the bundle to protect the insulation.

Our MI cable manufacturing facility in Calgary, Canada gives us adequate capacity to service the demands of clients in the oil sands projects of Western Canada in a time efficient manner. The facility’s strategic location has enabled us to expand our sale of MI cable, which is well-suited for high temperature applications and harsh, arctic environments, into a global business.

We maintain quality control testing standards in all of our manufacturing operations and perform various quality control checks on our products during the manufacturing process. We believe that our highly automated manufacturing process and multiple quality control checkpoints create high levels of operational efficiency.

Purchasing Strategy—We have multiple suppliers for all of our critical raw materials, including polymer, graphite, copper and stainless steel. For each of these raw materials, a minimum of two suppliers are selected and approved. We evaluate pricing and performance of these suppliers annually. For our low-volume custom-built electronic controller components, we select a single supplier based on past performance reliability and monitor the process closely as volumes are too low to divide this product over multiple suppliers. Our purchase specifications are usually based on industry or manufacturer standards. Testing of the raw materials is performed and documented by our suppliers and is reviewed by us at the time of receipt.

Distribution—We maintain three central distribution centers located in San Marcos, Texas, Calgary, Alberta and the Netherlands. Inventory is typically shipped directly from these distribution centers to customers, the construction site or our regional sales agents or distributors. Our sales agents may maintain “safety stocks” of core products to service the immediate MRO/UE requirements of customers who are time-sensitive and cannot wait for delivery from one of the central distribution centers. In the United States, a network of agents maintains safety stocks of core products. In Canada, customers are serviced from the central distribution center in Calgary. In Europe, customers are serviced from the central distribution center in the Netherlands. In Asia, safety stock of materials are kept in Yokohama, Japan; Seoul, Korea; Shanghai, China; Pune, India and Melbourne, Australia. Safety stocks are also warehoused in Moscow, Russia.

7

Table of Contents

Customers

We serve a broad base of large multinational customers, many of which we have served for almost 60 years. We have a diversified revenue mix with thousands of customers. None of our customers represented more than 10% of total revenues in fiscal 2012.

Sales and Marketing

Our direct sales force, consisting of 94 employees, is focused on positioning us with major end-users and EPC companies during the development phase of Greenfield projects with the goal of providing reliable, cost-effective heat tracing solutions. We utilize a network of more than 100 independent sales agents and distributors in over 30 countries to provide local support to customer facilities for MRO/UE. We actively participate in the growth and development of the domestic and international heat tracing standards established in the countries in which we sell products. We believe that we have established credibility as a reliable provider of high quality heat tracing products. In addition, we believe that our 14 registered trademarks in the United States and numerous additional brand names are recognized globally, giving us excellent brand recognition.

Standards and Certifications—We continually test our products to demonstrate that they can withstand harsh operating environments. Our heating cable products and associated design practices are subjected to various tests, including heat output, thermal stability and long-term aging, with the goal of producing products capable of performing at or beyond the expectations of our customers. All products are further tested and certified by various approval agencies to verify compliance with applicable industry standards.

Our products comply with national and international heat tracing industry standards such as ANSI/IEEE-515 in the United States, Canadian Standards Association 130.03 in Canada; International Electrical Commission 60079-30-1 in Europe, IECEx in Australia and ANSI/IEC in the Middle East. We also hold product certifications from approval agencies around the world.

Competition

The global industrial electric heat tracing industry is fragmented and consists of approximately 40 companies, which typically only serve discrete local markets and provide a limited service offering. We believe that we are the second largest participant in the industrial electric heat tracing market and one of only a few solutions providers with a comprehensive suite of products and services, global capabilities and local on-site presence. Our most significant competitor is Tyco Thermal Controls, a subdivision of Tyco International Ltd. In March 2012, Tyco announced that it had reached a definitive agreement to spin off and merge its Flow Control business (which includes its Thermal Controls division) with Pentair, Inc. (NYSE: PNR), a manufacturer of water pumps, water filtration products and enclosures for electronics and electrical components in an all-stock merger valued at $4.6 billion. The transaction is subject to the approval of the planned spin-off by Tyco shareholders, the approval of the merger by Pentair shareholders, regulatory approvals and customary closing conditions and is expected to be completed at the end of September 2012. We do not currently anticipate any adverse impact to our competitive position in the global heat tracing industry as a result of the Tyco-Pentair transaction.

Heat tracing providers differentiate themselves through value-added services, long-term customer relationship management and the ability to provide a full range of solutions. We differentiate ourselves from local providers by a global footprint, a full suite of products and services and a track record with some of the largest multinational energy, chemical processing, power and EPC companies in the world. In addition, we are dedicated solely to providing thermal solutions, whereas some of our competitors’ thermal solutions operations constitute only one of numerous operating segments.

Intellectual Property and Technology

The heat tracing industry is highly competitive and subject to the introduction of innovative techniques and services using new technologies. We have at least 40 registered patents in the United States, some of which have foreign equivalents. Of our United States registered patents, seven remain active, along with several foreign equivalents. While we have patented some of our products and processes, we historically have not relied upon patents to protect our design or manufacturing processes or products, and our patents are not material to our operations or business. Instead, we rely significantly on maintaining confidential our trade secrets, manufacturing know-how and other proprietary rights and other information related to our operations. Accordingly, we require all employees to sign a nondisclosure agreement to protect our trade secrets, business strategy and other proprietary information. We have 14 registered trademarks in the United States and an additional 20 recognized brand names. We also rely on a significant number of unregistered trademarks, primarily abroad, but also in the United States, in the day-to-day operation of our business.

8

Table of Contents

Research and Development

Our research and development group is focused on identifying new technologies to enhance our industrial heat tracing solutions through identifying opportunities to maximize product reliability and reduce the customer’s total cost of ownership, which consists of capital expenses, maintenance costs and energy costs. Current initiatives include conductive polymer technology research and the development of integrated control systems and advanced communication software for our electric heat tracing systems.

Employees

As of March 31, 2012, we employed approximately 755 persons on a full-time basis worldwide. None of our employees is covered by a collective-bargaining agreement, and we have never experienced any organized work stoppage or strike. We consider our employee relations to be good.

Governmental Regulation

Due to the international scope of our operations, we are subject to complex United States and foreign laws governing, among others, anti-corruption matters, export controls, economic sanctions, antiboycott rules, currency exchange controls and transfer pricing rules. These laws are administered, among others, the U.S. Department of Justice, the SEC, the Internal Revenue Service, Customs and Border Protection, the Bureau of Industry and Security, the Office of Antiboycott Compliance, or OAC, and the Office of Foreign Assets Control, or OFAC, as well as the counterparts of these agencies in foreign countries. Our policies mandate compliance with these laws. Despite our training and compliance programs, no assurances can be made that we will be found to be operating in full compliance with, or be able to detect every violation of, any such laws. For example, we paid penalties of $176,000 and $14,613 in 2009 to BIS and OFAC, respectively, to settle allegations that certain of our subsidiaries had committed apparent export control and economic sanctions violations that we voluntarily disclosed to the agencies. In August 2010, we paid a penalty of $32,500 to OAC to settle allegations that certain of our subsidiaries had committed apparent violations of antiboycott laws. We cannot predict the nature, scope or effect of future regulatory requirements to which our international operations might be subject or the manner in which existing laws might be administered or interpreted.

Environmental Compliance

Our operations and properties are subject to a variety of federal, state, local and foreign environmental laws and regulations, including those governing the discharge of pollutants into the air or water, the management and disposal of hazardous substances or wastes, the cleanup of contaminated sites, the emission of greenhouse gases, and workplace health and safety. Certain environmental laws, including the Comprehensive Environmental Response, Compensation, and Liability Act, impose joint and several liability for cleanup costs, without regard to fault, on persons who have disposed of or released hazardous substances into the environment. In addition, we could become liable to third parties for damages resulting from the disposal or release of hazardous substances into the environment. Some of our sites are affected by soil and groundwater contamination relating to historical site operations, which could require us to incur expenses to investigate and remediate the contamination in compliance with environmental laws. Some of our operations require environmental permits and controls to prevent and reduce air and water pollution, and these permits are subject to modification, renewal and revocation by issuing authorities. A failure to obtain, maintain, and comply with these permit requirements could result in substantial penalties, including facility shutdowns. From time to time, we could be subject to requests for information, notices of violation, and/or investigations initiated by environmental regulatory agencies relating to our operations and properties, Violations of environmental and health and safety laws can result in substantial penalties, civil and criminal sanctions, permit revocations, and facility shutdowns. Environmental and health and safety laws may change rapidly and have tended to become more stringent over time. As a result, we could incur costs for past, present, or future failure to comply with all environmental and health and safety laws and regulations. In addition, we could become subject to potential regulations concerning the emission of greenhouse gasses, and while the effect of such future regulations cannot be determined at this time, they could require us to incur substantial costs in order to achieve and maintain compliance. In the ordinary course of business, we may be held responsible for any environmental damages we may cause to our customers’ premises.

ITEM 1A. RISK FACTORS

The following risk factors address the material risks concerning our business. If any of the risks discussed in this annual report were to occur, our business, prospects, financial condition, results of operation and our ability to service our debt could be materially and adversely affected and the trading price of our common stock could decline significantly. Some statements in this annual report, including statements in the following risk factors, constitute forward-looking statements. Please refer to the section entitled “Forward-Looking Statements.”

9

Table of Contents

Risks Related to Our Business and Industry

The markets we serve are subject to general economic conditions and cyclical demand, which could harm our business and lead to significant shifts in our results of operations from quarter to quarter that make it difficult to project long-term performance.

Our operating results have been and may in the future be adversely affected by general economic conditions and the cyclical pattern of certain industries in which our customers and end users operate. Demand for our products and services depends in large part upon the level of capital and maintenance expenditures by many of our customers and end users, in particular those in the energy, chemical processing and power generation industries, and firms that design and construct facilities for these industries. These customers’ expenditures historically have been cyclical in nature and vulnerable to economic downturns. Prolonged periods of little or no economic growth could decrease demand for oil and gas which, in turn, could result in lower demand for our products and a negative impact on our results of operations and cash flows. In addition, this historically cyclical demand may lead to significant shifts in our results of operations from quarter to quarter, which limits our ability to make accurate long-term predictions about our future performance.

A sustained downturn in the energy industry, due to oil and gas prices decreasing or otherwise, could decrease demand for some of our products and services, which could materially and adversely affect our business, financial condition and results of operations.

A significant portion of our revenue historically has been generated by end-users in the upstream oil and gas markets. The businesses of most of our customers in the energy industry are, to varying degrees, cyclical and historically have experienced periodic downturns. Profitability in the energy industry is highly sensitive to supply and demand cycles and commodity prices, which historically have been volatile, and our customers in this industry historically have tended to delay large capital projects, including expensive maintenance and upgrades, during industry downturns. Customer project delays may limit our ability to realize value from our backlog as expected and cause fluctuations in the timing or the amount of revenue earned and the profitability of our business in a particular period. In addition, such delays may lead to significant fluctuations in results of operations from quarter to quarter, making it difficult to predict our financial performance on a quarterly basis.

Demand for a significant portion of our products and services depends upon the level of capital expenditure by companies in the energy industry, which depends, in part, on energy prices. Prices of oil and gas have been very volatile over the past four years, with significant increases until achieving historic highs in July 2008, followed immediately by a steep decline through 2009 and moderate increases from 2010 to early 2012. A sustained downturn in the capital expenditures of our customers, whether due to a decrease in the market price of oil and gas or otherwise, may delay projects, decrease demand for our products and services and cause downward pressure on the prices we charge, which, in turn, could have a material adverse effect on our business, financial condition and results of operations. Such downturns, including the perception that they might continue, could have a significant negative impact on the market price of our common stock.

As a global business, we are exposed to economic, political and other risks in a number of countries, which could materially reduce our revenues, profitability or cash flows or materially increase our liabilities. If we are unable to continue operating successfully in one or more foreign countries, it may have a material adverse effect on our business and financial condition.

For fiscal 2012, approximately 66% of our revenues were generated outside of the United States, and approximately 35% were generated outside North America. In addition, one of our key growth strategies is to continue to expand our global footprint in emerging and high growth markets around the world, although we may not be successful in expanding our international business.

Conducting business outside the United States is subject to additional risks, including the following:

· changes in a specific country’s or region’s political, social or economic conditions, particularly in emerging markets;

· trade relations between the United States and those foreign countries in which our customers and suppliers have operations, including protectionist measures such as tariffs and import or export licensing requirements;

· restrictions on our ability to own or operate subsidiaries in, expand in and repatriate cash from, foreign jurisdictions;

· exchange controls and currency restrictions;

· the burden of complying with multiple and potentially conflicting laws;

· potentially negative consequences from changes in U.S. and foreign tax laws;

· difficulty in staffing and managing (including ensuring compliance with internal policies and controls) geographically widespread operations;

10

Table of Contents

· different regulatory regimes controlling the protection of our intellectual property;

· difficulty in the enforcement of contractual obligations in non-U.S. jurisdictions and the collection of accounts receivable from foreign accounts; and

· transportation delays or interruptions.

One or more of these factors could prevent us from successfully expanding our presence in international markets, could have a material adverse effect on our revenues, profitability or cash flows or cause an increase in our liabilities. We may not succeed in developing and implementing policies and strategies to counter the foregoing factors effectively in each location where we do business.

A failure to deliver our backlog on time could affect our future sales and profitability and our relationships with our customers, and if we were to experience a material amount of modifications or cancellations of orders, our sales could be negatively impacted.

Our backlog is comprised of the portion of firm signed purchase orders or other written contractual commitments received from customers that we have not recognized as revenue. The dollar amount of backlog as of March 31, 2012 was $117.7 million. The timing of our recognition of revenue out of our backlog is subject to a variety of factors that may cause delays, many of which, including fluctuations in our customers’ delivery schedules, are beyond our control. Such delays may lead to significant fluctuations in results of operations from quarter to quarter, making it difficult to predict our financial performance on a quarterly basis. For example, a delay in the completion of a large Greenfield project resulted in approximately several million dollars in revenue attributable to such project being realized in the quarter ended September 30, 2010, which was one quarter later than expected. Further, while we have historically experienced few order cancellations and the amount of order cancellations has not been material compared to our total contract volume, if we were to experience a significant amount of cancellations of or reductions in purchase orders, it would reduce our backlog and, consequently, our future sales and results of operations.

Our ability to meet customer delivery schedules for our backlog is dependent on a number of factors including, but not limited to, access to raw materials, an adequate and capable workforce, engineering expertise for certain projects, sufficient manufacturing capacity and, in some cases, our reliance on subcontractors. The availability of these factors may in some cases be subject to conditions outside of our control. A failure to deliver in accordance with our performance obligations may result in financial penalties and damage to existing customer relationships, our reputation and a loss of future bidding opportunities, which could cause the loss of future business and could negatively impact our financial performance.

Our future revenue depends in part on our ability to bid and win new contracts. Our failure to effectively obtain future contracts could adversely affect our profitability.

Our future revenue and overall results of operations require us to successfully bid on new contracts and, in particular, contracts for large Greenfield projects, which are frequently subject to competitive bidding processes. Our revenue from major projects depends in part on the level of capital expenditures in our principal end markets, including the energy, chemical processing and power generation industries. The number of such projects we win in any year fluctuates, and is dependent upon the number of projects available and our ability to bid successfully for such projects. Contract proposals and negotiations are complex and frequently involve a lengthy bidding and selection process, which is affected by a number of factors, such as competitive position, market conditions, financing arrangements and required governmental approvals. For example, a client may require us to provide a bond or letter of credit to protect the client should we fail to perform under the terms of the contract. If negative market conditions arise, or if we fail to secure adequate financial arrangements or required governmental approvals, we may not be able to pursue particular projects, which could adversely affect our profitability.

We may be unable to compete successfully in the highly competitive markets in which we operate.

We operate in competitive domestic and international markets and compete with highly competitive domestic and international manufacturers and service providers. The fragmented nature of the industrial electric heat tracing industry, which consists of approximately 40 companies, makes the market for our products and services highly competitive. A number of our direct and indirect competitors are major multinational corporations, some of which have substantially greater technical, financial and marketing resources than us, and additional competitors may enter these markets. Our competitors may develop products that are superior to our products, develop methods of more efficiently and effectively providing products and services, or adapt more quickly than we do to new technologies or evolving customer requirements. Any increase in competition may cause us to lose market share or compel us to reduce prices to remain competitive, which could result in reduced sales and earnings.

11

Table of Contents

Volatility in currency exchange rates may adversely affect our financial condition, results of operations or cash flows.

We may not be able to effectively manage our exchange rate and/or currency transaction risks. Volatility in currency exchange rates may decrease our revenues and profitability, adversely affect our liquidity and impair our financial condition. While we have entered into hedging instruments to manage our exchange rate risk as it relates to certain intercompany balances with certain of our foreign subsidiaries, these hedging activities do not eliminate this exchange rate risk, nor do they reduce risk associated with total foreign sales.

Our non-U.S. subsidiaries generally sell their products and services in the local currency, but obtain a significant amount of their products from our facilities located in another country, primarily the United States, Canada or Europe. In particular, significant fluctuations in the Canadian Dollar, the Russian Ruble, the Euro or the Pound Sterling against the U.S. Dollar could adversely affect our results of operations. We also bid for certain foreign projects in U.S. Dollars or Euros. If the U.S. Dollar or Euro strengthens relative to the value of the local currency, we may be less competitive in bidding for those projects. See Item 7A, “Quantitative and Qualitative Disclosures about Market Risk” for additional information regarding our foreign currency exposure relating to operations.

In order to meet our global cash management needs, we often transfer cash between the United States and foreign operations and sometimes between foreign entities. In addition, our debt service requirements are primarily in U.S. Dollars and a substantial portion of our cash flow is generated in foreign currencies, and we may need to repatriate cash to the United States in order to meet our U.S. debt service obligations, including on our senior secured notes. These transfers of cash expose us to currency exchange rate risks, and significant changes in the value of the foreign currencies relative to the U.S. Dollar could limit our ability to meet our debt obligations, including under our senior secured notes, and impair our financial condition.

Because our consolidated financial results are reported in U.S. Dollars, and we generate a substantial amount of our sales and earnings in other currencies, the translation of those results into U.S. Dollars can result in a significant decrease in the amount of those sales and earnings. In addition, fluctuations in currencies relative to the U.S. Dollar may make it more difficult to perform period-to-period comparisons of our reported results of operations.

Due to the nature of our business, we may be liable for damages based on product liability claims. We are also exposed to potential indemnity claims from customers for losses due to our work or if our employees are injured performing services.

We face a risk of exposure to claims in the event that the failure, use or misuse of our products results, or is alleged to result, in death, bodily injury, property damage or economic loss. Although we maintain quality controls and procedures, we cannot be sure that our products will be free from defects. If any of our products prove to be defective, we may be required to replace the product. In addition, we may be required to recall or redesign such products, which could result in significant unexpected costs. Some of our products contain components manufactured by third parties, which may also have defects. In addition, if we are installing our products, we may be subject to claims that our installation caused damage or loss. Our products are often installed in our customers’ or end users’ complex and capital intensive facilities in inherently hazardous or dangerous industries, including energy, chemical processing and power generation, where the potential liability from risk of loss could be substantial. Although we currently maintain product liability coverage, which we believe is adequate for the continued operation of our business, we cannot be certain that this insurance coverage will continue to be available to us at a reasonable cost or, if available, will be adequate to cover any potential liabilities. With respect to components manufactured by third-party suppliers, the contractual indemnification that we seek from our third-party suppliers may be insufficient to cover claims made against us. In the event that we do not have adequate insurance or contractual indemnification, product liabilities could have a material adverse effect on our business, financial condition or results of operations.

Under our customer contracts, we often indemnify our customers from damages and losses they incur due to our work or services performed by us, as well as for losses our customers incur due to any injury or loss of life suffered by any of our employees or our subcontractor’s personnel occurring on our customer’s property. Many, but not all, of our customer contracts include provisions designed to limit our potential liability by excluding consequential damages and lost profits from our indemnity obligations. However, substantial indemnity claims may exceed the amount of insurance we maintain and could have a material adverse effect on our reputation, business, financial condition or results of operations.

A material disruption at any of our manufacturing facilities could adversely affect our results of operations.

If operations at any of our manufacturing facilities were to be disrupted as a result of significant equipment failures, natural disasters, power outages, fires, explosions, terrorism, adverse weather conditions, labor disputes or other reasons, we may be unable to fill customer orders and otherwise meet customer demand for our products, which could adversely affect our financial performance. For example, our marketing and research & development buildings, located on the same campus as our corporate headquarters and primary manufacturing facility in San Marcos, Texas, were destroyed by a tornado in January 2007.

12

Table of Contents

Interruptions in production, in particular at our manufacturing facilities in San Marcos, Texas, or Calgary, Canada, at which we manufacture the majority of our products, could increase our costs and reduce our sales. Any interruption in production capability could require us to make substantial capital expenditures to fill customer orders, which could negatively affect our profitability and financial condition. We maintain property damage insurance that we believe to be adequate to provide for reconstruction of facilities and equipment, as well as business interruption insurance to mitigate losses resulting from any production interruption or shutdown caused by an insured loss. However, any recovery under our insurance policies may not offset the lost sales or increased costs that may be experienced during the disruption of operations, which could adversely affect our financial performance.

Our international operations and non-U.S. subsidiaries are subject to a variety of complex and continually changing laws and regulations and, in particular, export control regulations.

Due to the international scope of our operations, we are subject to a complex system of laws and regulations, including regulations issued by the U.S. Department of Justice, or the DOJ, the SEC, the Internal Revenue Service, or the IRS, Customs and Border Protection, the Bureau of Industry and Security, or BIS, the Office of Antiboycott Compliance, or OAC, and the Office of Foreign Assets Control, or OFAC, as well as the counterparts of these agencies in foreign countries. While we believe we are in material compliance with these regulations and maintain programs intended to achieve compliance, we may currently or may in the future be in violation of these regulations. In 2009, we entered into settlement agreements with BIS and OFAC, and in 2010, we entered into a settlement agreement with OAC, in each case with respect to matters we voluntarily disclosed to such agencies.

Any alleged or actual violations may subject us to government scrutiny, investigation and civil and criminal penalties and may limit our ability to export our products or provide services outside the United States. Additionally, we cannot predict the nature, scope or effect of future regulatory requirements to which our international operations might be subject or the manner in which existing laws might be administered or interpreted.

In addition, our geographically widespread operations, coupled with our relatively smaller offices in many countries and our reliance on third party subcontractors, suppliers and manufacturers in the completion of our projects, make it more difficult to oversee and ensure that all our offices and employees comply with our internal policies and control procedures. We have in the past experienced employee theft, although the amounts involved have not been material, and we cannot assure you that we can ensure compliance with our internal control policies and procedures.

We operate in many different jurisdictions and we could be adversely affected by violations of the U.S. Foreign Corrupt Practices Act and similar foreign anti-corruption laws.

The U.S. Foreign Corrupt Practices Act, which we refer to as the FCPA, and similar foreign anti-corruption laws generally prohibit companies and their intermediaries from making improper payments or providing anything of value to influence foreign government officials for the purpose of obtaining or retaining business or obtaining an unfair advantage. Recent years have seen a substantial increase in the global enforcement of anti-corruption laws, with more frequent voluntary self-disclosures by companies, aggressive investigations and enforcement proceedings by both the DOJ and the SEC resulting in record fines and penalties, increased enforcement activity by non-U.S. regulators, and increases in criminal and civil proceedings brought against companies and individuals. Because many of our customers and end users are involved in infrastructure construction and energy production, they are often subject to increased scrutiny by regulators. Our internal policies mandate compliance with these anti-corruption laws. We operate in many parts of the world that are recognized as having governmental corruption problems to some degree and where strict compliance with anti-corruption laws may conflict with local customs and practices. Our continued operation and expansion outside the United States, including in developing countries, could increase the risk of such violations in the future. Despite our training and compliance programs, we cannot assure you that our internal control policies and procedures always will protect us from unauthorized reckless or criminal acts committed by our employees or agents. In the event that we believe or have reason to believe that our employees or agents have or may have violated applicable anti-corruption laws, including the FCPA, we may be required to investigate or have outside counsel investigate the relevant facts and circumstances, which can be expensive and require significant time and attention from senior management. Violations of these laws may result in severe criminal or civil sanctions, which could disrupt our business and result in a material adverse effect on our reputation, business, results of operations or financial condition.

Our dependence on subcontractors could adversely affect our results of operations.

We often rely on third party subcontractors as well as third party suppliers and manufacturers to complete our projects. To the extent that we cannot engage subcontractors or acquire supplies or materials, our ability to complete a project in a timely fashion or at a profit may be impaired. If the amount we are required to pay for these goods and services exceeds the amount we have estimated in bidding for fixed-price contracts, we could experience losses on these contracts. In addition, if a subcontractor or supplier is unable to deliver its services or materials according to the negotiated contract terms for any reason, including the deterioration of its financial condition or over-commitment of its resources, we may be required to purchase the services or materials from another source

13

Table of Contents

at a higher price. This may reduce the profit to be realized or result in a loss on a project for which the services or materials were needed.

We may lose money on fixed-price contracts, and we are exposed to liquidated damages risks in many of our customer contracts.

We often agree to provide products and services under fixed-price contracts, including our turnkey solutions. Under these contracts, we are typically responsible for all cost overruns, other than the amount of any cost overruns resulting from requested changes in order specifications. Our actual costs and any gross profit realized on these fixed-price contracts could vary from the estimated costs on which these contracts were originally based. This may occur for various reasons, including errors in estimates or bidding, changes in availability and cost of labor and raw materials and unforeseen technical and logistical challenges, including with managing our geographically widespread operations and use of third party subcontractors, suppliers and manufacturers in many countries. These variations and the risks inherent in our projects may result in reduced profitability or losses on projects. Depending on the size of a project, variations from estimated contract performance could have a material adverse impact on our operating results. In addition, many of our customer contracts, including fixed-price contracts, contain liquidated damages provisions in the event that we fail to perform our obligations thereunder in a timely manner or in accordance with the agreed terms, conditions and standards.